We are professional China Custom Vinyl Fence Manufacturers with fences virgin PVC/Vinyl material and UV Protected.

The heart of an electric fence is the wire - it's both the "highway" for the current and the "warning line" for animals or intruders to perceive. Choosing the wrong wire or using the wrong wire can lead to a fence failure or even a safety hazard. This in-depth guide focuses on practical details to help you accurately select, install and maintain electric fence wire.

1. Detailed Explanation of Electric Fence Wire Types: Matching Your Core Needs

Electric fence wire is not "one size fits all". Different materials and structures determine its performance, lifespan and application scenarios:

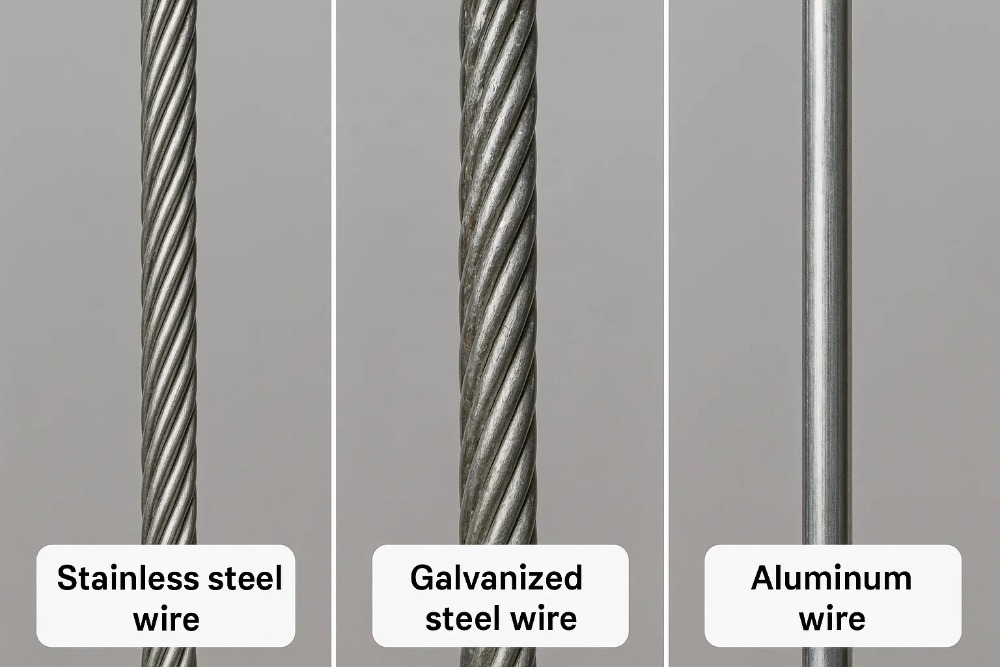

Stainless steel wire:

Advantages: Excellent conductivity (lowest resistance, high current transmission efficiency), extremely durable (corrosion resistance, stretch resistance, lifespan up to 20-30 years), low maintenance (almost no rust).

Disadvantages: Highest cost.

Suitable for: Permanent fences, critical lines of defense, high conductivity requirements, highly corrosive environments (coastal, near manure areas).

Galvanized steel wire:

Advantages: High strength (especially high-tension models), low cost, relatively durable.

Disadvantages: Moderate conductivity (higher resistance than stainless steel), will rust (after coating wear or damage), medium life (about 10-15 years, greatly affected by the environment).

Applicable: Medium- and long-term fencing with limited budget, fencing that requires high strength (such as large livestock), areas where conductivity requirements are not the highest.

Aluminum wire:

Advantages: Excellent conductivity (close to stainless steel), light weight, and lowest cost.

Disadvantages: Lowest strength (easy to stretch and sag), easy to oxidize (surface oxide layer increases resistance, which requires a pulser to overcome), short life (about 5-10 years).

Applicable: Temporary fencing, short-term projects with very low budgets, weight-sensitive applications (such as mobile fences).

Comparison table of core types of electric fence wires

| Features | Stainless steel wire | Galvanized steel conductor | Aluminum conductor |

| Conductivity | Best | Medium | Excellent |

| Strength | High | Very high | Low |

| Corrosion resistance | Excellent | Medium (depends on coating) | Poor (easy to oxidize) |

| Lifespan | Extremely long (20+ years) | Medium (10-15 years) | Shorter (5-10 years) |

| Cost | Highest | Medium | Lowest |

| Best applications | Permanent fences, critical areas | Medium to long term, strength required | Temporary, low cost |

2. Interpretation of key parameters of electric fences: It is not just as simple as thickness

When choosing a wire, be sure to pay attention to these core parameters:

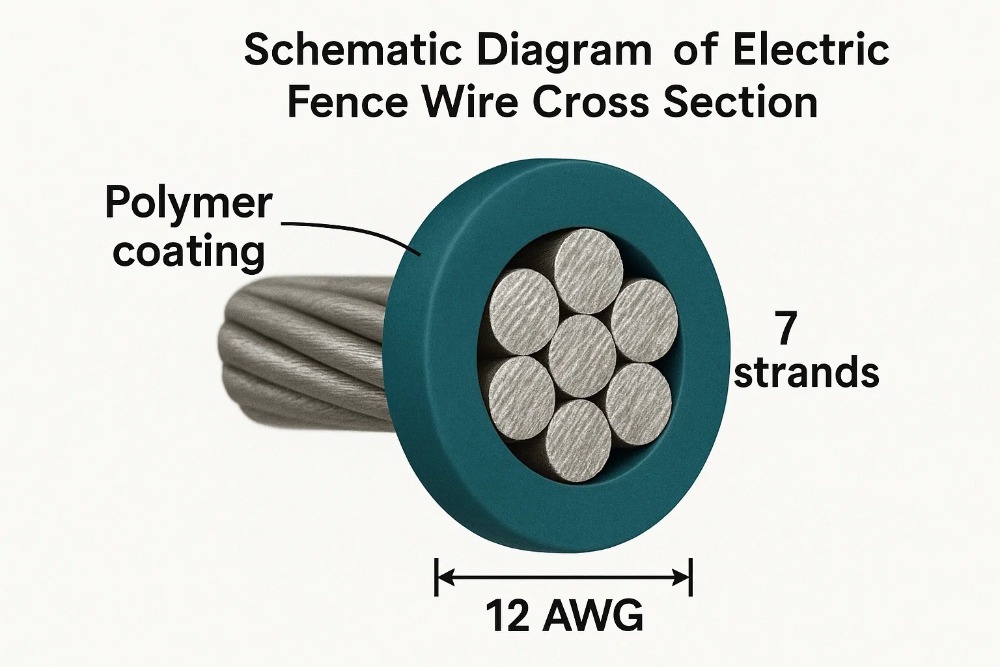

Wire diameter (Gauge):

Indicated by AWG (American Wire Gauge), the smaller the number, the thicker the wire.

Thick wire (12.5-14 AWG): Low resistance, good conductivity, high strength, suitable for long distances, critical defense lines, and large livestock.

Medium wire (16-17 AWG): Most commonly used, balancing cost, conductivity and strength, suitable for most livestock and general protection.

Thin wire (18 AWG+): The lowest cost, but high resistance, low strength, easy to break, only suitable for short distances, small animals or temporary/low-risk areas.

Recommendation: 14 or 16 AWG is preferred for primary defense lines, long distances, and large animals; 17 AWG is optional for secondary wires and short distances.

Strands:

Refers to how many thin metal wires are twisted together inside a single wire.

Solid: High strength, but poor flexibility, prone to fatigue fracture at bends.

Stranded: Good flexibility, strong fatigue resistance, more durable (especially on uneven terrain or vulnerable to impact). Common ones include 7-strand and 19-strand. Stranded wire is highly recommended!

Coating:

Bare: Most common, performance depends on the substrate itself.

Polymer Coated:

Advantages: Significantly increases corrosion resistance (especially for galvanized steel), provides an insulating layer (reduces accidental contact with weeds/supports), and increases visibility (optional high-visibility colors).

Disadvantages: Slightly increases cost.

Recommendation: Coated wire is a wise investment in humid, corrosive, or weedy environments.

3. Practical installation and maintenance of electric fences: ensure efficiency and reliability

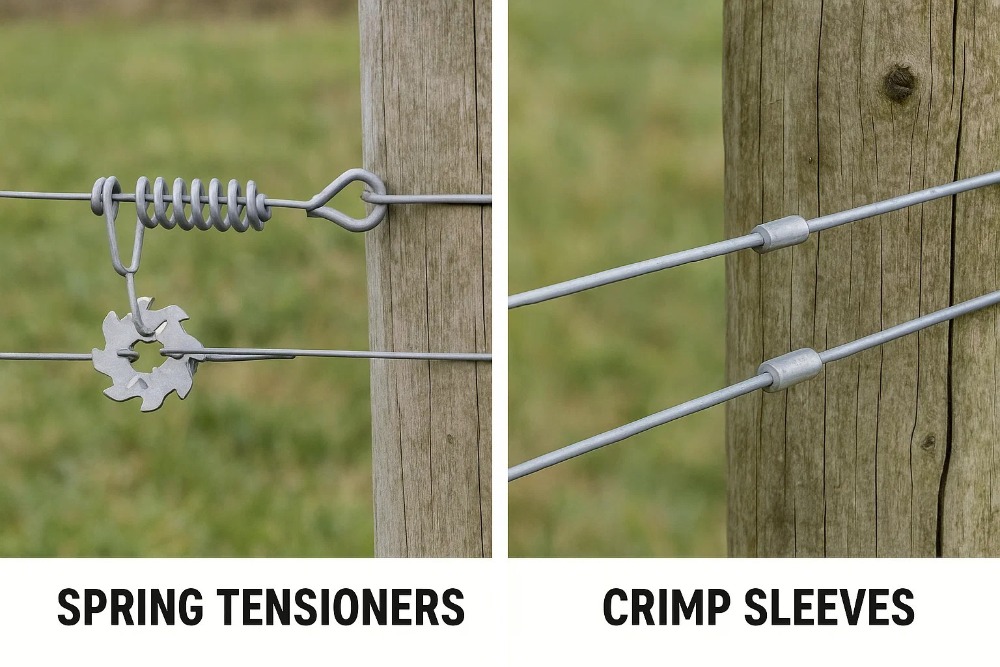

Tension is the key:

Tight! Loose wires are very likely to contact the ground or vegetation, causing leakage, greatly weakening the effect of the electric shock. Use a dedicated fence tensioner or spring loaded strainer to apply and maintain constant tension.

Installation tips: The wire should be wrapped around the tensioner shaft at least 3 times and the end should be firmly fixed. Use corner posts and braces to provide strong support at long distances or corners.

Tensioner type selection:

Ratchet tensioner: Provides maximum pulling force, suitable for permanent fences and main conductors with high tension requirements.

Spring tensioner: Automatically compensates for thermal expansion and contraction caused by temperature changes, preventing the wire from breaking in winter or excessive relaxation in summer. Highly recommended for use in long fences.

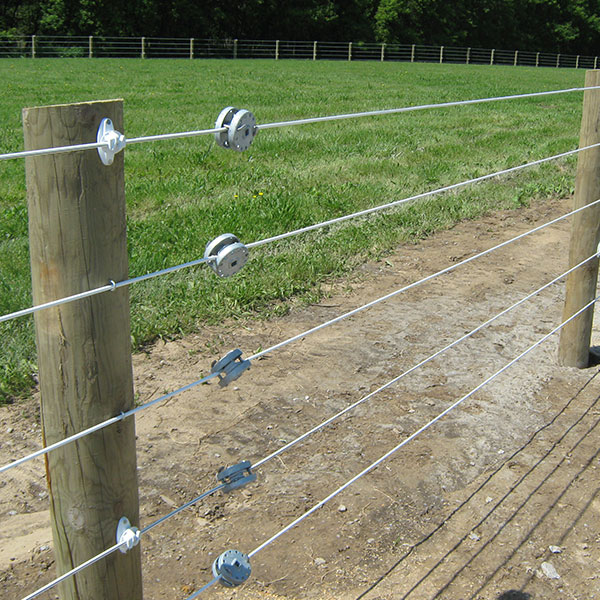

Insulators are a guarantee of safety:

The wire must be fixed to the bracket (wooden stakes, T-shaped steel posts, etc.) through high-quality insulators. Damaged, aged or contaminated insulators (dust, salt, bird droppings) will cause current leakage ("short circuit").

Selection principle: Select the rated voltage of the insulator according to the pulser output voltage (usually it should be higher than the pulser voltage). In high-voltage systems or humid areas, ceramic insulators or heavy plastic insulators are preferred. Avoid using cheap, easily aged plastic insulators.

Installation points: Make sure that the wire is firmly in the insulator groove and does not have any contact with the bracket. Regularly check whether the insulator is clean and crack-free.

The connection must be reliable:

The connection points between wires and wires and wires and leads are the most common failure points. Always use special electric fence clips (Fence Clips) or crimp sleeves (Crimp Sleeves) and use crimping pliers (Crimping Tool) to make a firm, low-resistance connection. Absolutely avoid simple twisting!

Connector type:

Sawtooth clip/alligator clip: Convenient for temporary connection or testing, not suitable for permanent connection.

Crimp wire clip/sleeve: Provides the most reliable and lasting connection with the lowest resistance, and is the first choice for permanent fences.

4. Quick troubleshooting table for common problems with electric fences: Treat the symptoms

Is the electric fence not working well? Check the wire system first!

| Fault phenomenon | Possible causes (wire related) | Troubleshooting and solution steps |

| Weak or no electric shock | 1. Broken wires 2. Severe loosening of wires in contact with the ground/vegetation 3. Corrosion, loosening or disconnection of connection points 4. Insulator failure leading to leakage 5. Using thin wires resulting in excessive resistance over long distances |

1. Check along the fence section by section and repair the breakpoints 2. Tighten the wire and remove the contact 3. Check all connection points, clean and reconnect or replace 4. Check and clean insulators and replace damaged parts 5. Check the pulser load capacity and consider thickening the wire or shortening the single wire length/adding parallel wires |

| Frequent wire breakage | 1. Excessive tension (especially in winter) 2. Insufficient tension causes shaking and wear/being hit by animals 3. The bracket spacing is too large and the wire span is too long 4. Use low-strength wire (such as thin aluminum wire) 5. The wire rubs against the bracket/insulator |

1. Use spring tensioners to compensate for thermal expansion and contraction 2. Maintain proper tension 3. Shorten the distance between brackets (usually 3-5 meters) 4. Replace with high-strength conductors (such as galvanized steel or stainless steel) 5. Ensure that the conductors are smooth in the insulator grooves without sharp edges |

| Fence overgrown with weeds affects the effect | 1. The wire height is too low or loose 2. Failure to use coated wire to reduce leakage |

1. Adjust the height of the wire and tighten it 2. Regularly clear weeds along the fence 3. Consider switching to polymer-coated wire |

5. Safety First: A Rule You Can’t Ignore

Clear Warnings: Install standard electric fence warning signs (yellow background with black lightning symbol) in prominent locations such as along the fence, at the entrance and exit. This is a legal requirement and a moral responsibility!

Stay away from public areas: Make sure the fence does not extend onto public roads, sidewalks or other people’s property to avoid accidental contact.

Grounding System: Electric fences must be equipped with a properly installed grounding stake system (usually at least 3, deep into the moist soil, with a spacing of >3 meters), otherwise the current cannot form a loop and the electric shock is ineffective! Check the grounding resistance regularly (should be <10Ω).

Lightning Protection: In areas prone to lightning, install a lightning arrester (Lightning Arrestor) at the input of the pulser to protect the pulser from being damaged by lightning.

Action Checklist: Choose and Install Your Electric Fence Wire

Clear Goals: What to Protect Against? (Cows? Sheep? Pigs? Thieves?) Is it permanent or temporary?

Choose Materials: Permanent/Critical/Corrosive Environment → Stainless Steel; Limited Budget/Strength Required → Galvanized Steel; Temporary/Extremely Low Cost → Aluminum.

Specification: Primary wire/long distance/large animals → 14 or 16 AWG; General/secondary wire → 16 or 17 AWG. Always choose multi-strand wire! Wet/grassy areas → polymer coated wire.

Accessories: High-quality insulators (selected by voltage), special tensioners (ratchet or spring), crimping clamps/sleeves and crimping pliers, warning signs.

Installation: Ensure firm support (corner posts, support posts), tighten wires (with tensioners), reliable connections (crimping), fix wires through insulators, install grounding system and warning signs.

Regular maintenance: Check tension, clean insulators, remove weeds, check connection points and wire condition.

Choose the right wire, install accurately, and maintain regularly, and your electric fence will become a reliable, efficient and long-lasting defense line! Investing in the right wire and accessories can save a lot of maintenance time and cost in the long run and ensure the fence is used to the maximum effect.

English

English  中文简体

中文简体