We are professional China Custom Vinyl Fence Manufacturers with fences virgin PVC/Vinyl material and UV Protected.

Electric fencing has become an indispensable solution for livestock management, property security, and wildlife control. It offers a cost-effective, flexible, and long-lasting means to establish boundaries without the heavy infrastructure required by traditional fencing systems. Yet, one of the most frequently misunderstood aspects of electric fencing is the distinction between high-tensile and low-tensile electric fence wire.

These two types of fencing wire are designed for different purposes and environments. Their strength, flexibility, installation requirements, and maintenance needs can dramatically affect the performance and durability of your electric fence system. Understanding their differences is essential for selecting the right type for your specific application—whether you’re enclosing cattle, protecting crops, or setting up a perimeter for wildlife deterrence.

1. Understanding Tensile Strength in Fence Wire

Before delving into the differences, it’s important to define tensile strength.

Tensile strength refers to the maximum amount of tension (or pulling force) a material can withstand before breaking. It’s measured in pounds per square inch (PSI) or newtons per square millimeter (N/mm²). In fencing terms, higher tensile strength means the wire can endure more stress without stretching or snapping.

This property directly influences how well the fence maintains tension across long distances, how often it needs re-tightening, and how resistant it is to animal pressure, weather, or physical impact.

2. What Is High-Tensile Electric Fence Wire?

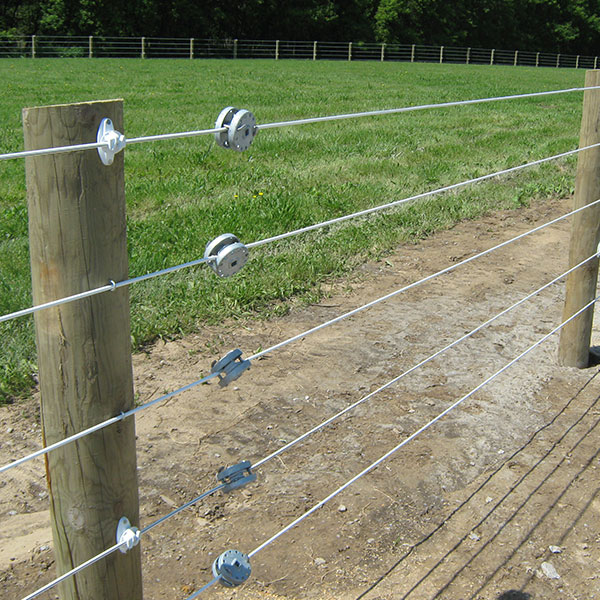

High-tensile wire is made from carbon steel with a higher carbon content—typically around 0.28% to 0.32%. This composition gives the wire its remarkable strength and rigidity. High-tensile electric fence wire can withstand pulling forces of up to 200,000 PSI, which makes it suitable for long fence lines and demanding outdoor conditions.

Because of its strength, it can be stretched tight without sagging. Once properly tensioned, it maintains its shape and effectiveness for many years, even under the strain of large livestock or environmental stress such as wind, snow, or falling branches.

Key Characteristics:

- Diameter: Often 12.5-gauge, though variations exist.

- Material: High-carbon steel.

- Breaking strength: Approximately 1,300–1,500 pounds.

- Coating: Commonly galvanized or zinc-aluminum alloy for corrosion resistance.

- Stretch resistance: Minimal; maintains tension over long distances.

- Durability: Can last 20–40 years with minimal maintenance.

3. What Is Low-Tensile Electric Fence Wire?

Low-tensile wire—sometimes called soft wire—is made from mild steel with lower carbon content (typically below 0.15%). This makes it more ductile and easier to work with but less resistant to tension and stretching.

Low-tensile wire can handle only about 60,000 to 90,000 PSI, which limits its effective use for long spans or heavy-duty fencing applications. However, its flexibility makes it suitable for shorter fences or temporary enclosures where ease of handling and installation speed are more important than long-term structural rigidity.

Key Characteristics:

- Diameter: Often available in 14–16 gauge.

- Material: Mild (low-carbon) steel.

- Breaking strength: Around 500–800 pounds.

- Coating: Usually galvanized for corrosion protection.

- Stretch resistance: Higher; requires regular retightening.

- Durability: Typically lasts 5–10 years, depending on exposure and use.

4. Structural and Physical Differences

| Property | High-Tensile Wire | Low-Tensile Wire |

| Material | High-carbon steel | Mild (low-carbon) steel |

| Tensile Strength | Up to 200,000 PSI | 60,000–90,000 PSI |

| Breaking Load | 1,300–1,500 lbs | 500–800 lbs |

| Elasticity | Very low (retains tension) | High (stretches easily) |

| Installation Difficulty | Requires tools and skill | Easier to install manually |

| Maintenance Needs | Minimal | Frequent tightening needed |

| Durability | 20–40 years | 5–10 years |

| Cost per Foot | Slightly higher | Lower upfront cost |

| Best for | Permanent, long-term fencing | Short-term or low-stress fencing |

5. Performance and Application Differences

a. Tension and Sag Resistance

The key performance difference lies in how each wire holds tension.

High-tensile wire can be stretched tightly—up to 250 pounds of tension—without permanent deformation. This tightness prevents sagging between posts and allows greater spacing between them, often up to 80–100 feet apart.

Low-tensile wire, by contrast, tends to stretch under pressure. The wire sags between posts more easily and loses effectiveness if not re-tensioned periodically. This can lead to inconsistent voltage distribution and weaker deterrent power along the fence.

b. Shock Efficiency

An electric fence works by delivering a short, sharp electric pulse when an animal contacts the wire. For this system to function reliably, electrical continuity must be consistent.

High-tensile wire, because it remains taut and well-insulated, provides superior conductivity and consistent shocking power across long distances.

Low-tensile wire can develop weak points if the strands loosen or oxidize, leading to voltage drops that reduce the fence’s overall effectiveness.

c. Weather and Corrosion Resistance

Both types are usually galvanized, but high-tensile wire’s thicker coating and higher-grade steel improve its resistance to rust and environmental degradation. Some modern high-tensile wires use zinc-aluminum alloy coatings that can last three to four times longer than traditional galvanization.

Low-tensile wire’s coating may wear faster, especially in humid or coastal regions, leading to corrosion and breakage over time.

6. Installation Differences

a. Ease of Handling

Low-tensile wire is soft and pliable, which makes it easy to bend, cut, and tie by hand. Farmers who prefer quick installations often find it more forgiving when setting up small paddocks or temporary enclosures.

High-tensile wire, however, requires specialized tools—tensioners, gripples, or ratchet strainers—to stretch and secure it properly. The wire is springy and under high stress, so installation demands more caution and experience. However, once installed correctly, it needs little ongoing adjustment.

b. Post Spacing

Because high-tensile wire remains taut, fence posts can be placed farther apart—sometimes up to twice the distance required for low-tensile fences. This can offset the higher cost of the wire itself, as fewer posts and less labor are needed.

c. Safety Precautions

Working with high-tensile wire under tension requires care. The wire can recoil with dangerous force if it snaps or slips during installation. Always wear protective gloves, safety glasses, and long sleeves. Low-tensile wire, on the other hand, poses far less recoil risk.

7. Cost Considerations

Upfront costs for high-tensile fencing can appear higher due to the wire’s quality and the need for tensioning hardware. However, its longevity and low maintenance often make it the more economical choice over time.

A properly installed high-tensile fence may last up to four times longer than a comparable low-tensile fence, with fewer repairs and less wire replacement.

Low-tensile fencing, though cheaper at first, may demand frequent retightening, replacement of corroded sections, and higher maintenance costs—especially in areas exposed to animals or severe weather.

8. Choosing the Right Type for Your Needs

The best choice depends on your specific application, terrain, livestock, and budget. Here’s a general guideline:

Choose High-Tensile Wire If:

- You need a long-lasting, low-maintenance fence.

- You are enclosing large areas or strong animals such as cattle, horses, or deer.

- The terrain allows straight, long fence runs.

- You want to minimize the number of posts and overall maintenance time.

- You are building a permanent installation.

Choose Low-Tensile Wire If:

- You need a temporary or seasonal fence.

- You are enclosing smaller animals (sheep, goats, or pets) in modest areas.

- You prioritize ease of setup over long-term durability.

- Your terrain is irregular and requires frequent bending of wire.

- You are on a limited budget for short-term fencing.

9. Maintenance and Longevity Tips

For High-Tensile Wire:

- Check tension annually; minor adjustments may suffice.

- Keep insulators clean and ensure posts remain stable.

- Use corrosion-resistant fittings and keep vegetation clear from the fence line.

- Inspect for lightning or impact damage periodically.

For Low-Tensile Wire:

- Regularly re-tension the wire to prevent sagging.

- Replace any corroded or rusted sections quickly.

- Keep fence lines free of weeds that may short the system.

- Apply a protective coating in coastal or humid environments to slow corrosion.

10. Environmental and Operational Impact

High-tensile fencing is often regarded as environmentally friendlier because it uses fewer materials (thanks to greater post spacing) and has a longer lifespan, reducing waste over time.

Moreover, its consistent performance minimizes the risk of livestock escapes or wildlife entanglement, promoting safer containment practices. Low-tensile fences, though less durable, can be more easily dismantled or repositioned—useful for rotational grazing or short-term applications.

11. Summary: Striking the Right Balance

In short, the difference between high-tensile and low-tensile electric fence wire comes down to strength, longevity, and purpose. High-tensile wire delivers unmatched durability, structural stability, and long-term efficiency, making it the clear choice for permanent installations and large-scale agricultural use.

Low-tensile wire, however, offers greater flexibility and ease of use—an excellent solution for smaller properties, temporary pens, or users with limited tools and experience.

Both types play valuable roles in fencing design. By understanding their distinctions and aligning them with your operational needs, you can construct a fence that delivers maximum performance, safety, and value for years to come.

12. Final Thoughts

When choosing between high-tensile and low-tensile electric fence wire, don’t focus solely on cost. Consider the total lifespan, maintenance effort, and livestock behavior. A well-chosen fence is more than just a physical barrier—it’s an investment in security, efficiency, and peace of mind.

Whether you prioritize strength or simplicity, permanent infrastructure or flexibility, the right choice ensures your electric fence performs exactly as needed—safely, reliably, and cost-effectively.

English

English  中文简体

中文简体