We are professional China Custom Vinyl Fence Manufacturers with fences virgin PVC/Vinyl material and UV Protected.

For property owners, farm managers, and construction professionals, a fence is more than a boundary line; it’s a long-term investment in security, safety, and organization. Whether it’s containing livestock, securing a worksite, or defining a property perimeter, the integrity of that fence is paramount. Traditional rigid mounting methods—using nails, screws, and U-posts—have been the default for decades. However, these methods come with significant, often overlooked, drawbacks that lead to premature wear, constant repairs, and escalating costs.

A modern solution that is rapidly gaining traction is the use of flexible fence strap. These simple yet ingenious devices are revolutionizing how we think about fence installation and longevity. This article will delve into the mechanics of flexible fencing systems, exploring how they directly combat the primary causes of fence failure, dramatically enhance durability, and, as a result, significantly reduce long-term maintenance expenditures.

The Hidden Weakness of Traditional Rigid Fence Attachment

To understand the value of a flexible solution, we must first identify the problems inherent in rigid attachment systems.

The Problem of Concentrated Stress Points: When fence mesh (like chain link, welded wire, or field fence) is directly fastened to a post with nails or clips, all force is transferred to those tiny, rigid points of contact. An animal leaning against the fence, wind creating lateral pressure, or even the natural expansion and contraction of materials due to temperature changes focuses immense stress on these small areas. Over time, this leads to:

Broken Welds: On welded wire mesh, the welds at the attachment points can snap.

Stretched and Torn Mesh: The wires themselves can fatigue, stretch, and eventually tear around the hard edges of a nail or clip.

Damage to Posts: On wooden posts, repeated stress can enlarge nail holes, splinter the wood, and weaken the post’s integrity.

The Impact of Ground Movement and Frost Heave: In many climates, the ground doesn’t stay static. Frost heave occurs when water in the soil freezes and expands, lifting posts and the attached fence upward. When the ground thaws, the soil settles, but the fence often does not return to its original position. This annual cycle puts tremendous strain on a rigid system, leading to sagging, leaning posts, and failed attachments.

Corrosion at the Attachment Point: Where two different metals meet (e.g., a steel nail in a galvanized mesh loop), galvanic corrosion can occur. This electrochemical reaction accelerates rusting, severely weakening the connection point long before the rest of the fencing shows signs of wear. A rigid system ensures this corrosion is focused precisely where the fence’s strength is most critical.

These issues create a vicious cycle of inspection, tightening, re-nailing, and eventual panel replacement—a constant drain on time and financial resources. This is where the paradigm shift to a flexible attachment system comes into play.

What Are Flexible Fence Straps? Understanding the Solution

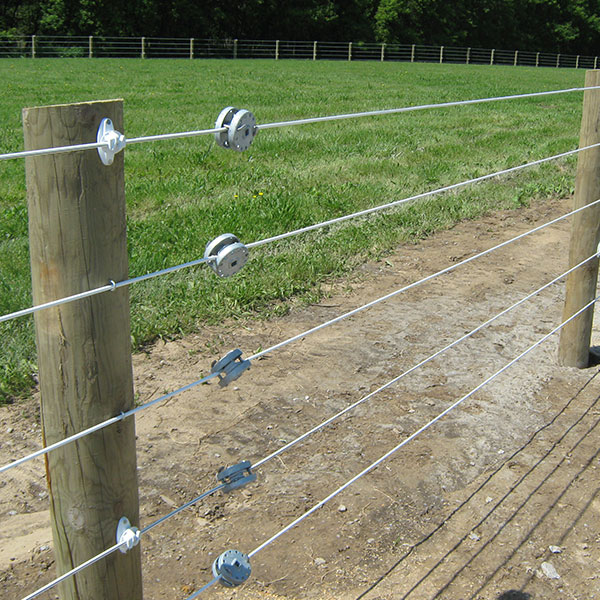

Flexible fence fasteners, often simply called fence straps or fence bands, are heavy-duty galvanized steel bands designed to secure fencing mesh to posts. Unlike a single nail, the strap is long and wide, distributing the force of the fence across a much broader surface area of the post.

They are typically installed by:

Wrapping the strap around the post and the fence line wire or mesh.

Threading the end of the strap through a pre-formed buckle or loop.

Pulling it tight with a tool like a fence stretcher or a simple wrench for smaller jobs.

The tension and friction hold the fence securely without the need for puncturing the post or the mesh.

This simple design is the key to their remarkable performance and is a cornerstone of a modern durable fencing system.

The Direct Link Between Flexibility and Enhanced Durability

The benefits of using straps are not merely theoretical; they are direct, mechanical responses to the failures of rigid systems.

Superior Force Distribution: This is the core advantage. Instead of concentrating stress on a few small points, a heavy-duty fence strap distributes the tension and pressure from the fence across the entire width and length of the band. This means the force of a 1,200-pound animal pushing against the fence is spread over 20-30 square inches of steel and post, rather than on a single nail head. This prevents the localized fatigue and tearing that destroy traditional fences.

Accommodates Movement Without Damage: A flexible strap system creates a semi-rigid fence connection. It holds the fence taut and secure but has a slight, intentional give. When posts shift due to frost heave or soil erosion, or when the fence receives a sudden impact, the straps allow for micro-movements. They flex and then return to their original position, absorbing the energy that would otherwise break a weld, bend a nail, or splinter a post. This impact-resistant fencing capability is crucial for high-traffic areas like livestock pens or equestrian facilities.

Eliminates Galvanic Corrosion Hotspots: High-quality fence straps are hot-dip galvanized, providing a thick, robust protective coating. Because the strap system does not require piercing the galvanized layer of the fence mesh (as a nail does), the integrity of the mesh’s corrosion protection remains intact. The strap itself acts as a uniform, sacrificial barrier. By preventing the creation of corrosion hotspots, the entire system’s lifespan is extended, making it a superior long-lasting fence material.

Preserves Post Integrity: Whether you’re using wooden posts, steel T-posts, or U-posts, straps protect your investment. They eliminate the need to drill holes or drive nails, which compromise the structural integrity and weatherproofing of wooden posts and the galvanization of metal posts. This leads to reduced fence post damage and a longer service life for the most expensive components of your fence.

Translating Durability into Tangible Maintenance Cost Reduction

The enhanced durability provided by flexible straps directly and dramatically impacts your bottom line. The reduction in maintenance costs is realized through several key channels:

Drastically Reduced Repair Visits: The most obvious saving is in labor. A fence that doesn’t break doesn’t need fixing. Property managers can shift from a reactive maintenance model (constantly responding to breaks and sagging) to a proactive one (occasional visual inspections). This means fewer man-hours spent on repairs, less fuel spent traveling the fence line, and fewer materials like spare nails, clips, or mesh panels needing purchase.

Elimination of Frequent Re-Tensioning: Traditional fences, especially wire fences, are notorious for losing tension and beginning to sag over time. This is not just an aesthetic issue; a sagging fence is a weak fence. Re-stretching an entire fence line is a labor-intensive, two-person job. A strap-secured fence maintains its tension far more effectively because the flexible connection absorbs the daily stresses that cause sagging. This leads to a low maintenance fence solution that stays taut for years.

Extended Lifespan of All Fencing Components: By protecting the mesh from tearing, the posts from splitting, and the connections from corroding, you are not just repairing less—you are replacing major components less often. The cost-effective agricultural fencing strategy isn’t about the cheapest upfront cost, but the lowest total cost of ownership. Spending slightly more on high-quality straps during installation can save you thousands of dollars in avoided post and mesh replacement over the fence’s 20+ year lifespan.

Improved Livestock Safety and Associated Costs: For agricultural users, a broken fence is more than an inconvenience; it’s a liability. Escaped livestock can cause damage, get injured, or be lost entirely. The superior strength and livestock fencing security provided by a strap system minimize the risk of breakouts, preventing potentially massive unforeseen costs and ensuring animal welfare.

Practical Applications: Where Flexible Straps Shine

Flexible fence straps are versatile and can be used across a wide range of applications:

Agricultural Fencing: Ideal for high-tensile wire fencing, field fence, and electric fence systems on both wooden and T-posts. They are perfect for corral fencing and pasture fencing where animal impact is a constant factor.

Industrial and Construction Fencing: For securing chain link panels around worksites, the ability to quickly install, tension, and later remove fencing without destroying posts is a huge advantage for temporary perimeter security.

Residential and Equestrian Use: Provides a clean, professional-looking installation for horse paddocks, arenas, and garden fencing that is both strong and safe for animals.

Vinyl and Coated Mesh Fencing: Straps are perfect for these systems as they secure the fence firmly without scratching or compromising the protective vinyl coating, which is essential for preventing rust.

Implementation: Best Practices for Installation

To maximize the benefits, proper installation is key. The process is straightforward but requires attention to detail.

Choose the Right Strap: Select a heavy-duty galvanized steel strap that is wide and thick enough for your application. For large livestock and high-tensile wire, a wider, thicker gauge (e.g., 1/2" x 0.080") is necessary. For lighter duties, a narrower option may suffice.

Prepare the Post: Ensure the post is set correctly and is solid.

Position the Fence: Hang the fence mesh on the post line at the desired height.

Apply the Strap: Wrap the strap around the post and the appropriate line wire (usually the top and bottom wires for field fence). Thread the end through the buckle.

Tension the Fence and Strap: Use a fence stretcher or come-along to pull the entire fence line taut. Once the fence is at the desired tension, pull the free end of the strap tight to secure it to the post. The tension of the fence will help keep the strap locked in place.

Secure the End: Some straps have a self-locking design, while others may require you to crimp the end or bend it back to prevent it from slipping. Always follow the manufacturer’s guidelines.

Conclusion: A Smart Investment for Long-Term Value

The initial investment in a system of flexible fence straps is minimal, especially when considered as a component of the total fencing project. However, the return on that investment is substantial and ongoing. By addressing the fundamental flaws of rigid attachment systems, these straps transform a vulnerable fence into a resilient, dynamic asset.

The result is a dramatic extension of the service life of all your fencing materials, a significant reduction in the time and money spent on annual upkeep, and the peace of mind that comes from a secure, reliable barrier. For anyone serious about building a fence that is designed to last, opting for a flexible attachment system is not just an alternative—it’s the modern, intelligent standard for durable fencing systems and cost-effective agricultural fencing. It is a simple upgrade that pays for itself many times over, making it one of the smartest decisions a property owner can make.

English

English  中文简体

中文简体